Control unit with touch screen

Product description

Its a device made to record and store the temperature and the current consumption of 1 or more furnaces.

It was built to operate in the lost wax casting enviroment for the retention of the datas of burn out furnaces and afterburners temperature.

FEATURES:

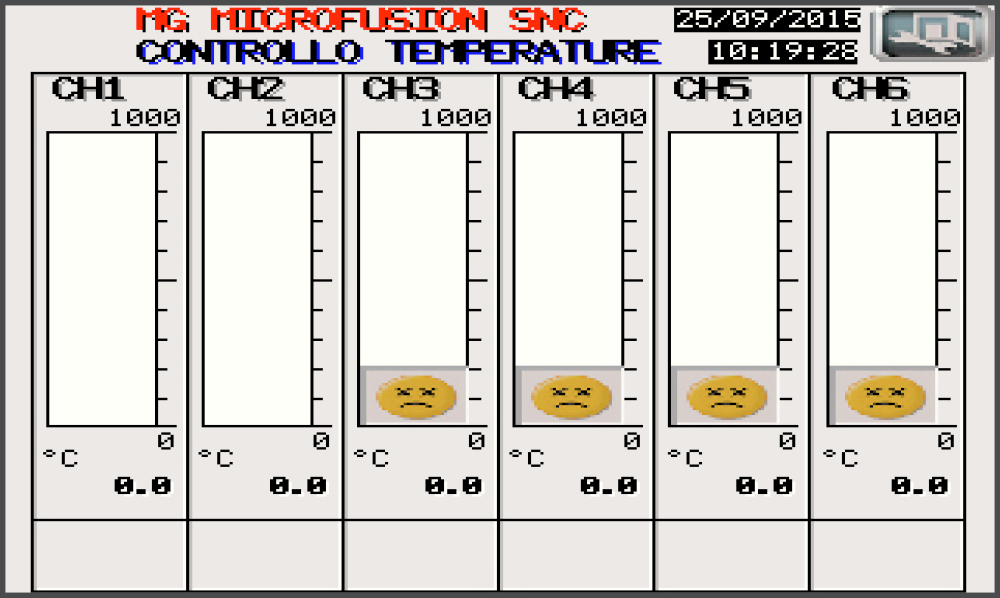

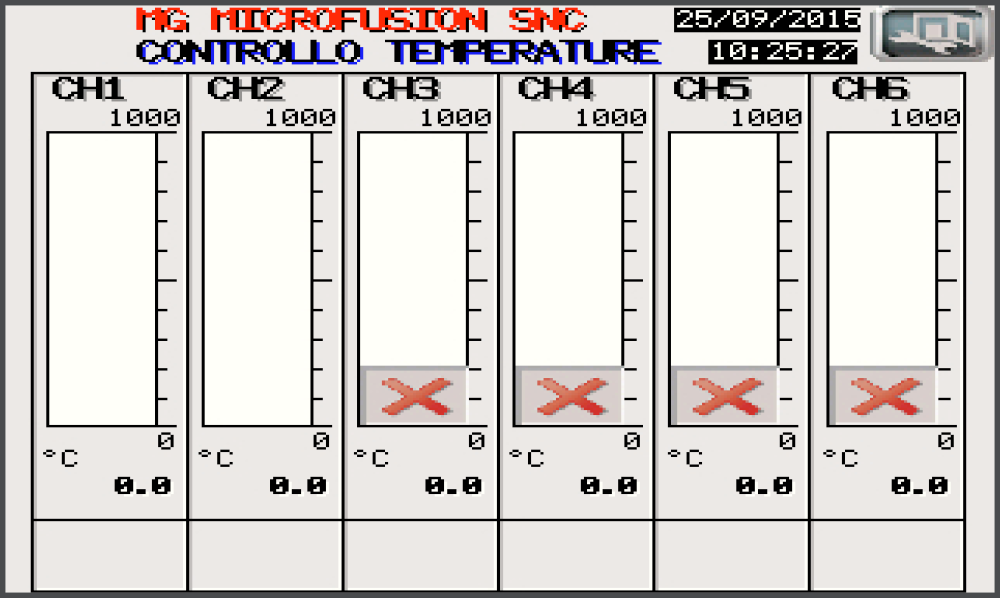

• The device can monitor datas of maximum 6 channels of temperature from furnace or/and afterburner.

(Ex. 6 furnaces or 3 furnaces and 3 afterburners).

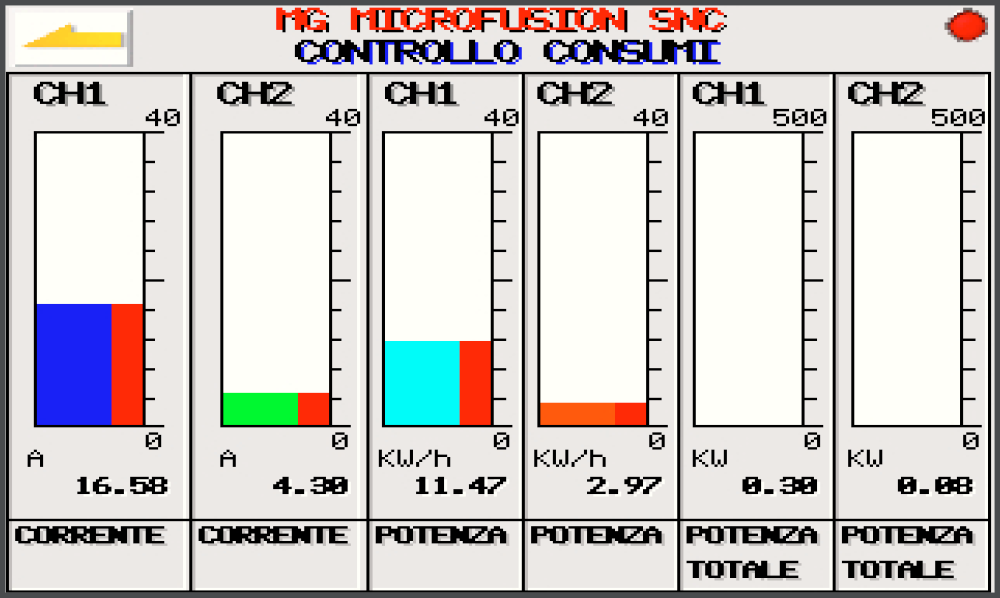

• It can monitor 2 assigned channels for the current consumption and establish Kilowatt absorption.

• The data storage can be set manually, cyclic or timed.

• The datas are saved in CSV format.

• The device is equipped with a touch screen control panel.

TRACKING:

The device allow the data tracking for any control by environmental agencies. This let you:

• The storage of data due by day

• The visualization of graphic temperatures and consumption.

• The availability of data in the network for the visualization with other software