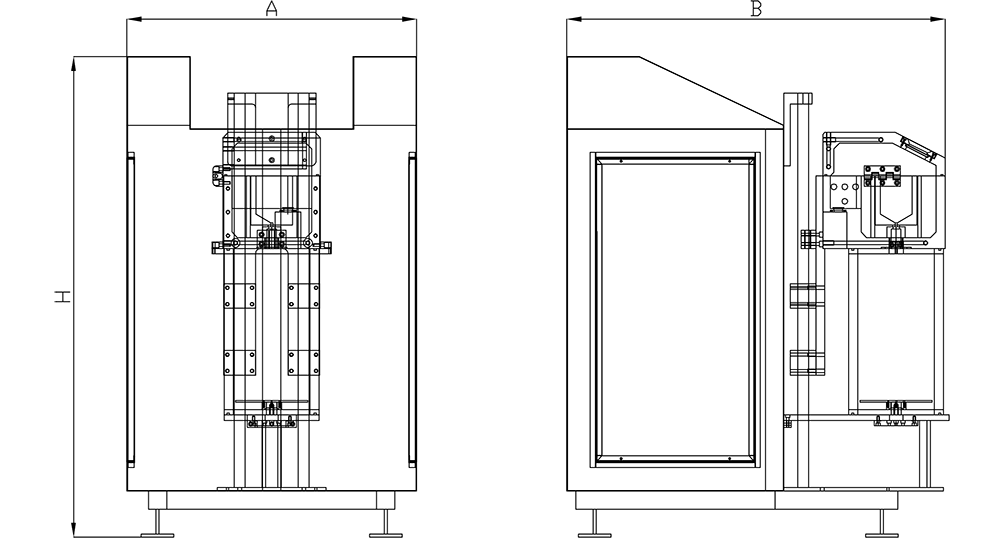

Product description

This machine was specifically studied to be used with precious and non precious alloys for jewellery .

The particular features of the flask loading,the separate pressure managment of the melting chamber and flask chamber,allow the customer to produce verythin wall thikness Jewellery with a smooth surface and a good finish.

FEATURES:

• AC line 3 phases 380-400 V

• Induction power 15 KW

• Maximum temperature 1300 °C

• Vacuum pump 25 m3/h

• Management of 2 different pressures, positive and negative

• positive pressure up to 200 mbar and negative up to -990 mbar In the upper chamber (crucible chamber)

• positive pressure up to 200 mbar and negative up to -990 mbar In the lower chamber (flask chamber)

• Flangeless flask : max 200mm Diam. X 400mm h

(perforated or unperforated)

• Less than 3 minutes to replace crucible and stopper

• Casting cycle time between 4 and 5 minutes.

• The casting cicle are controlled by a touch screen, and the software Is complete with:

a) Multiple programs. 50 programmable cycles

b) Management of the mixing of the alloy during the cast

c) Management of the pressurisation of the upper chamber after the load of the alloy

d) storage of casting data

e) casting data export with ethernet connection.