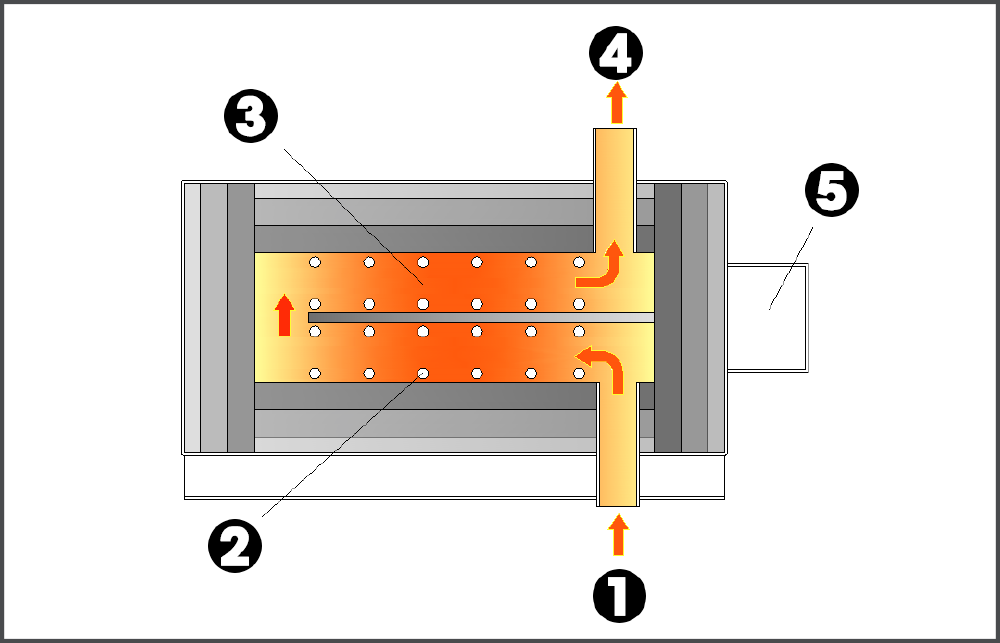

1 Air to be treated

2 Resistance

3 Oxidation at 900° C

4 Treated air at 700° C

5 Control unit

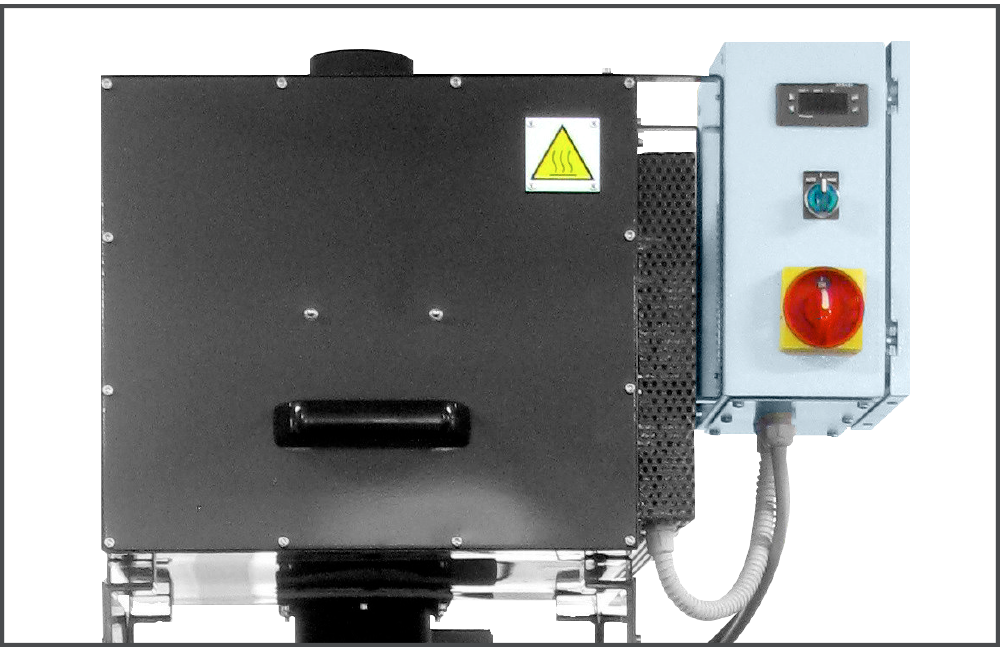

Afterburner frontal view.

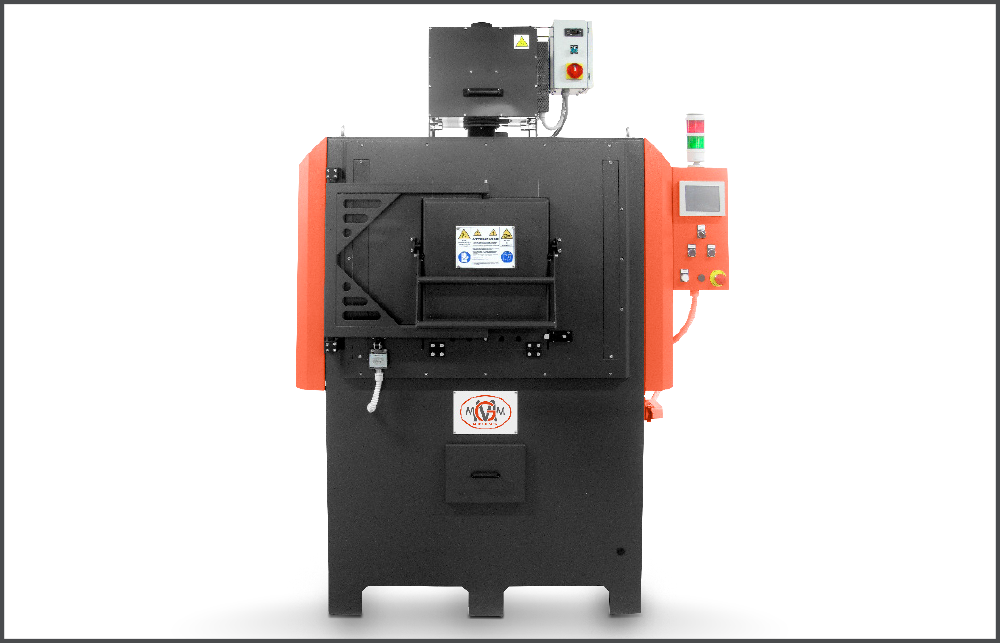

Example of an oven installation for annealing cylinders for lost wax casting.

Product description

It’ s a device perfect for the smoke cleaning, and it’s provided with a thermal system that is suitable to operate up to 900°C.

With the pourpose to transform the noxius element and to eliminate the polluting emission in the atmosphere.

It is different from the others for its small dimensions, for the use of electric power instead of gas and for the combustion.

It has been designed to operate in the lost wax casting environment and specifically with the burn out furnaces, but it can be used in other productive processes that expect: special weldings, acid emissions, fusion or paintings.

FEATURES:

For this device have been used ecological and latest generation materials that reduce considerably the temperature in the external walls and that improve the afterburner performances.

The energy consumption is reduced at the minimum thanks to the resistances control by means of PID function and with the use of high quality and latest generation materials.

The external structure is in painted strong metal sheet, studied to facilitate potential technical maintenance intervention.

MAXIMUM TEMPERATURE: 900°C;

DIMENSIONS: 68 cm X 71 cm X 60 cm (h)

26.7 in X 27.9 in X 23.6in (h)

WEIGHT: 75 Kg;

MODELS:

– NAC-PST-4: 4 Kw consumption

– NAC-PST-6: 6 Kw consumption

– NAC-PST-8: 8 Kw consumption

– NAC-PST-10: 10 Kw consumption